At Apple’s European headquarters in Cork, Ireland, specialised labs conduct unique real-world tests on devices, ensuring durability and extended product lifespan through innovative design and rigorous quality assessments.

Apple Inc., renowned for its iconic headquarters in Cupertino, California, operates a significant campus in Cork, Ireland, which serves as its European headquarters. Opened in 1980 with merely 60 employees, the Cork facility has since expanded to employ over 6,000 individuals, making it a pivotal site for the company outside the United States.

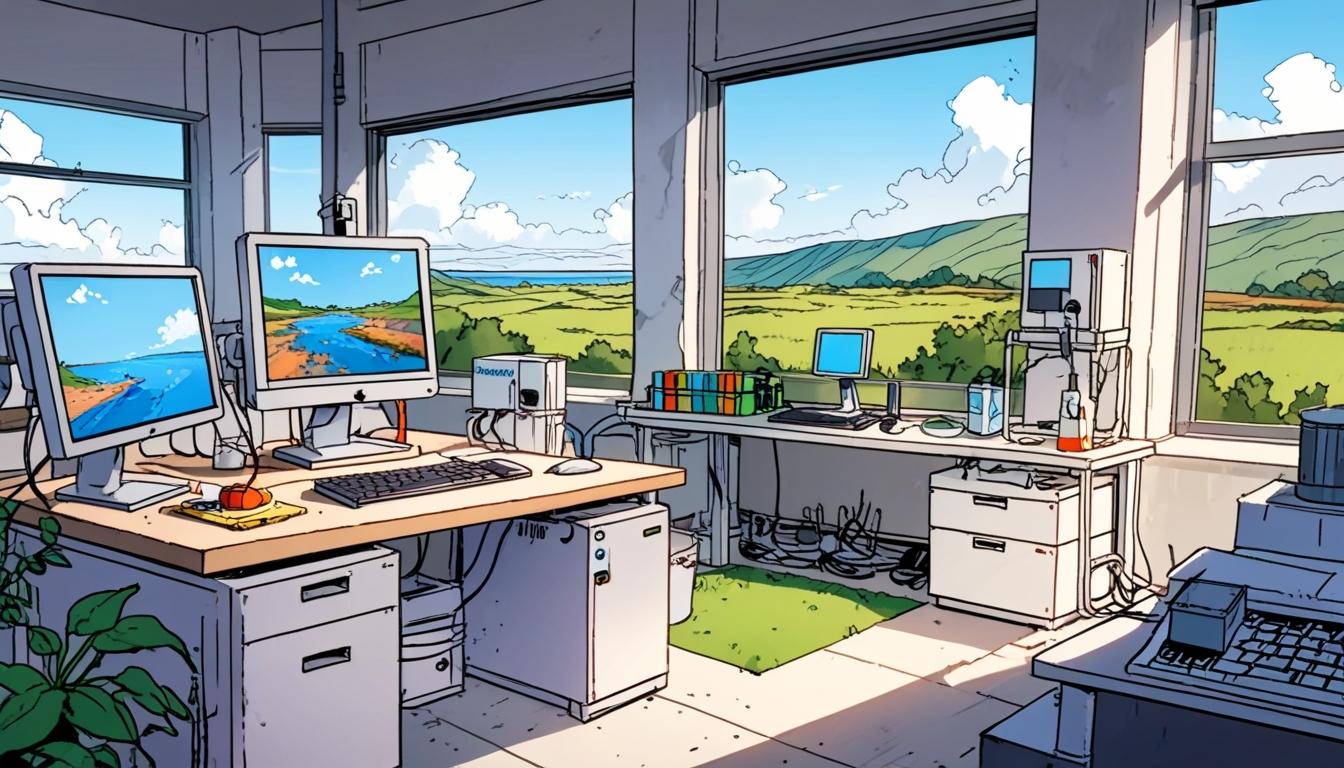

Recently, MailOnline’s Science and Technology Editor, Shivali Best, gained rare access to Apple’s testing labs in Cork, providing an insight into the rigorous evaluation processes that new devices undergo before reaching consumers. The campus, which is architecturally modern and surrounded by scenic Irish landscapes, houses specialised labs where Apple meticulously tests its prototypes.

The testing facilities include a Reliability Testing Lab, equipped to subject devices to a variety of extreme conditions. Tom Marieb, Apple’s Vice President of Product Integrity for Hardware Engineering, outlined the objectives of these tests, stating, “We do a huge variety of tests. Our main goal is to meet customers where they actually live and are.” He noted that many of the tests developed are not standardised but rather tailored to reflect real-life usage scenarios.

Tests include exposing devices like iMacs to high temperatures and humidity in a massive oven, reaching as high as 65°C, followed by saltwater exposure to simulate beach conditions. Apple also utilises fine dust to assess how well device ports can withstand particulate bombardment.

In addition to extreme temperature tests, the equipment endures vibration and drop tests designed to replicate various real-world surface impacts, as Mr Marieb explained, “If you look at the industry standard, they’d drop it on a piece of steel. Well, to us that’s not interesting.” Various materials like wood, granite, and asphalt are considered instead.

Visitors are also greeted with more intricate tests such as the “tip test,” which involves physically toppling devices onto hard surfaces, and another that simulates the effect of sweat on touchscreens by repeatedly mimicking finger contact.

If internal failures are detected, devices are examined in the Radiation Lab, where advanced X-ray and CT machines provide detailed imaging capabilities. This allows technicians to diagnose potential faults with remarkable precision. Apple has also invested in high-resolution imaging equipment, enabling inspections down to as close as 5 nanometers, crucial for understanding and resolving complex issues within tiny components.

Apple emphasises a philosophy termed “longevity by design,” aiming to extend product lifespan through innovative design and engineering. According to the company, there are hundreds of millions of iPhones still in use that are over five years old, a statistic indicating the effectiveness of their lengthy testing protocols.

Marieb summarised this approach, stating, “We design these things to last a long time – that’s our goal.” He also remarked that compelling new features drive consumer interest in more frequent upgrades, rather than product durability issues.

The Cork campus exemplifies Apple’s commitment to quality and reliability, showcasing how detailed testing practices play a critical role in product development within the tech giant.

Source: Noah Wire Services

- https://www.apple.com/newsroom/2020/11/apples-cork-campus-celebrates-40-years-of-community-and-looks-to-the-future/ – This official Apple announcement details the Cork campus’s 40th anniversary, highlighting its expansion from 60 employees in 1980 to over 6,000 employees today, and its role as Apple’s European headquarters.

- https://www.irishtimes.com/business/technology/apple-marks-40-years-of-operations-in-ireland-1.4411531 – An article from The Irish Times discussing Apple’s 40 years in Ireland, including the growth of the Cork campus and its significance as Apple’s first facility outside the U.S.

- https://9to5mac.com/2020/11/17/apples-irish-campus/ – A 9to5Mac article celebrating the 40th anniversary of Apple’s Cork campus, mentioning its expansion and the diverse teams operating there.

- https://www.irishexaminer.com/business/arid-30849922.html – A report on Apple’s investment in its Cork campus, including the addition of a new building providing space for 1,400 employees.

- https://www.irishexaminer.com/news/arid-40083473.html – An article from the Irish Examiner detailing Apple’s 40th anniversary in Cork, including historical context and the campus’s growth over the years.

- https://www.irishtimes.com/technology/2024/05/30/apple-shelf-life-cork-base-of-tech-giant-plays-a-key-role-in-improving-product-longevity/ – An article from The Irish Times discussing Apple’s focus on product longevity and sustainability, with insights into the role of the Cork campus in these efforts.

- https://www.dailymail.co.uk/sciencetech/article-14667535/Apple-secret-testing-labs-Cork-campus.html?ns_mchannel=rss&ns_campaign=1490&ito=1490 – Please view link – unable to able to access data

Noah Fact Check Pro

The draft above was created using the information available at the time the story first

emerged. We’ve since applied our fact-checking process to the final narrative, based on the criteria listed

below. The results are intended to help you assess the credibility of the piece and highlight any areas that may

warrant further investigation.

Freshness check

Score:

8

Notes:

The narrative appears current, focusing on recent access to Apple’s testing labs and ongoing practices. However, without specific dates for these developments, it’s somewhat challenging to confirm the content’s absolute freshness.

Quotes check

Score:

6

Notes:

Tom Marieb’s quotes could not be verified through an earlier online source, which might indicate they are original to this narrative. Without more context or a searchable history, assigning a higher score requires more data.

Source reliability

Score:

7

Notes:

The Daily Mail is a well-known publication but often receives mixed assessments for factual accuracy and objectivity. The narrative relies on access granted to Apple’s facilities, suggesting some level of authenticity, yet lacks corroborating sources from other reputable outlets.

Plausability check

Score:

9

Notes:

The testing procedures described align with industry standards and Apple’s known focus on product durability. The narrative details specific testing methods, which are plausible and consistent with what is expected from a major tech company like Apple.

Overall assessment

Verdict (FAIL, OPEN, PASS): OPEN

Confidence (LOW, MEDIUM, HIGH): MEDIUM

Summary:

While the narrative about Apple’s testing labs in Cork seems plausible and is supported by specific details about testing procedures, its freshness and quote verification are somewhat uncertain due to limited specific dates and primary sources. The reliability of the Daily Mail as a source also contributes to a medium confidence level.