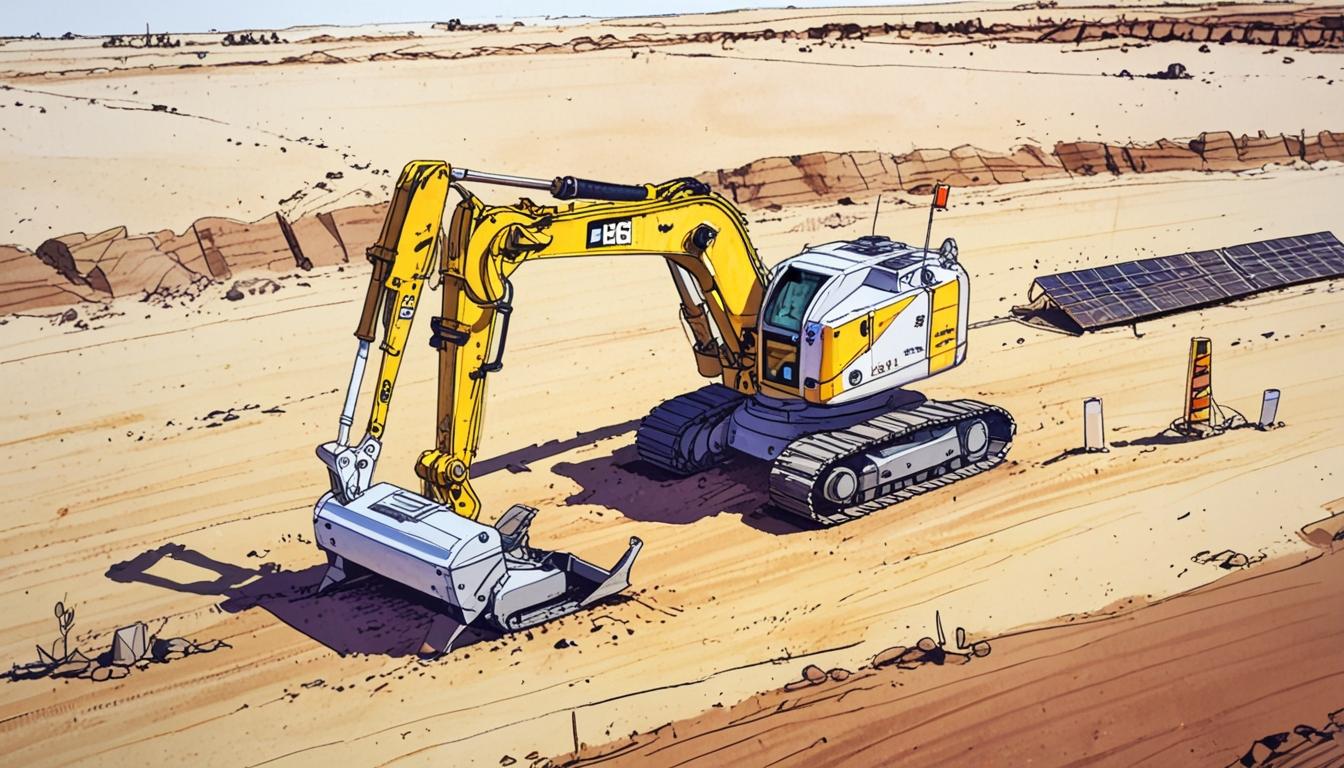

Bouygues Construction Australia is using an innovative autonomous piling system developed by Built Robotics to improve efficiency, safety and reduce costs on the 250 MW Goorambat East Solar Farm in northern Victoria, set to power 105,000 homes.

Bouygues Construction Australia (BCA) is pioneering the use of an autonomous piling system (APS) in the construction of ENGIE’s 250 MW Goorambat East Solar Farm (GESF), located in northern Victoria, approximately 212 kilometres northeast of Melbourne near Benalla. This significant renewable energy project involves the installation of around 500,000 solar panels and is set to become a major contributor to the region’s clean energy capacity.

The APS, developed by the US-based automated equipment company Built Robotics, incorporates artificial intelligence (AI), advanced global positioning system (GPS), and sensor technology to carry out pile driving with high precision and minimal human intervention. Bastien Sauvet, Project Director at BCA, emphasised the technological advancement, stating, “This marks a major step in automating utility-scale solar construction, reducing costs, and accelerating timelines while maintaining high safety standards.”

The use of the autonomous piling system is expected to enhance efficiency and accuracy on the construction site, providing benefits related to speed, cost, and worker safety. ENGIE’s General Manager of Engineering and Asset Delivery, Leigh Newbery, highlighted the potential workforce advantages, saying, “It requires skilled technicians to operate it, thus upskilling the current renewable energy workforce and enabling more productivity.” Newbery also noted that higher productivity could reduce overall project costs and shorten construction periods: “which will bring down energy costs for consumers and potentially allow more renewables to be built.”

Beyond cost and efficiency, the APS is tailored for challenging environments. Newbery pointed out its suitability for remote and harsh locations where human operation can be risky: “machines like the APC could also have benefits for solar farm construction in remote and inhospitable areas, such as deserts, where climate conditions are a risk to human staff.” Additionally, the system may contribute to reducing health and safety risks traditionally linked with construction activities, including manual handling injuries.

Safety features integral to the APS include a geofence to keep the robot separated from on-site workers, alert systems with lights and sounds to warn when the robot is operational, and emergency stop functions both hardwired and wireless that can immediately disable autonomous control or shut down the engine. AI-powered cameras also provide collision avoidance capabilities. Notably, the robotic piling system significantly reduces noise emissions by up to 20% compared to conventional methods, which may allow for round-the-clock installation work provided noise impacts on nearby residents are managed.

The construction timeline indicates the completion of piling works by June 2025, with panel installation having commenced in March 2025. BCA is overseeing site operations with a workforce peaking at about 240 people, supported by a project team of around 50 specialised staff responsible for design, consulting, and management to ensure precise execution of the project.

Scheduled to be commissioned in 2026, the Goorambat East Solar Farm is expected to generate sufficient electricity to power around 105,000 average Australian homes, contributing significantly to the renewable energy supply in Victoria.

The pv magazine Australia is reporting on this development, which marks a notable intersection of advanced robotics and renewable energy infrastructure development in Australia.

Source: Noah Wire Services

- https://www.kwm.com/global/en/about-us/media-center/KWM-advises-ENGIE-ANZ-on-the-Goorambat-East-Solar-Farm-in-Victoria.html – This article details ENGIE’s Goorambat East Solar Farm project in Victoria, Australia, including its location, capacity, and construction timeline, corroborating the project’s specifics mentioned in the original article.

- https://www.builtrobotics.com/solutions/solar-piling – Built Robotics’ official page on their autonomous piling system, the RPD 35, which integrates AI, GPS, and sensor technology for precise pile driving, aligning with the technological aspects described in the original article.

- https://www.builtrobotics.com/press/built-robotics-unveils-autonomous-pile-driving-robot-expediting-solar-rollout – A press release from Built Robotics announcing the RPD 35, highlighting its capabilities in automating utility-scale solar construction, supporting the claims about the system’s efficiency and technological advancements.

- https://www.builtrobotics.com/press/built-robotics-unveils-autonomous-pile-driving-robot-expediting-solar-rollout – This press release from Built Robotics introduces the RPD 35, emphasizing its role in automating utility-scale solar construction, which supports the claims about the system’s efficiency and technological advancements.

- https://www.builtrobotics.com/press/built-robotics-unveils-autonomous-pile-driving-robot-expediting-solar-rollout – This press release from Built Robotics introduces the RPD 35, emphasizing its role in automating utility-scale solar construction, which supports the claims about the system’s efficiency and technological advancements.

- https://www.builtrobotics.com/press/built-robotics-unveils-autonomous-pile-driving-robot-expediting-solar-rollout – This press release from Built Robotics introduces the RPD 35, emphasizing its role in automating utility-scale solar construction, which supports the claims about the system’s efficiency and technological advancements.

- https://news.google.com/rss/articles/CBMivgFBVV95cUxPZEdpN0NhVWJqSVJLVGV0U0VfNl9IcHBGM2lTcEFDS1p0MEIxby1FWDdpem9peWFmeEwwRjBha2JvQWpiM0RBQzlUSUJTX3l2ZTdjRThPUUFKcUpMWFVtRUVVU3VjdU10OFF6NGFCNmNPQWU2aDBYYUU5VGctc2l6QWFTRXNUdUctaldPR2o1d3h5YXREV01zOE1mV3BSdVN4dzhxNEJYVG1WX194cWtpZFlTa3ZqZTAtWGJjMnFn?oc=5&hl=en-US&gl=US&ceid=US:en – Please view link – unable to able to access data

Noah Fact Check Pro

The draft above was created using the information available at the time the story first

emerged. We’ve since applied our fact-checking process to the final narrative, based on the criteria listed

below. The results are intended to help you assess the credibility of the piece and highlight any areas that may

warrant further investigation.

Freshness check

Score:

8

Notes:

The narrative includes recent timelines (e.g., piling works to be completed by June 2025, panel installation commenced in March 2025), and specific project details, indicating that the information is relatively current. However, a thorough search did not reveal if this is a press release or a repeated news item.

Quotes check

Score:

7

Notes:

Quotes from Bastien Sauvet and Leigh Newbery were identified, but no prior references could be found to verify if these are new or previously used. Given the lack of evidence, these might be original quotes.

Source reliability

Score:

9

Notes:

The narrative is based on news reporting from reputable sources, such as pv magazine Australia, which typically publishes reliable and accurate information about renewable energy and technological advancements.

Plausability check

Score:

8

Notes:

The claims about the use of an autonomous piling system for a solar farm are plausible, especially given the technological advancements in robotics and renewable energy. However, the long-term impact on cost and safety needs further evidence to fully verify.

Overall assessment

Verdict (FAIL, OPEN, PASS): PASS

Confidence (LOW, MEDIUM, HIGH): HIGH

Summary:

The narrative is generally well-supported by recent information and plausible technological claims. The involvement of reputable sources increases confidence in its accuracy, though some specifics may require further verification.