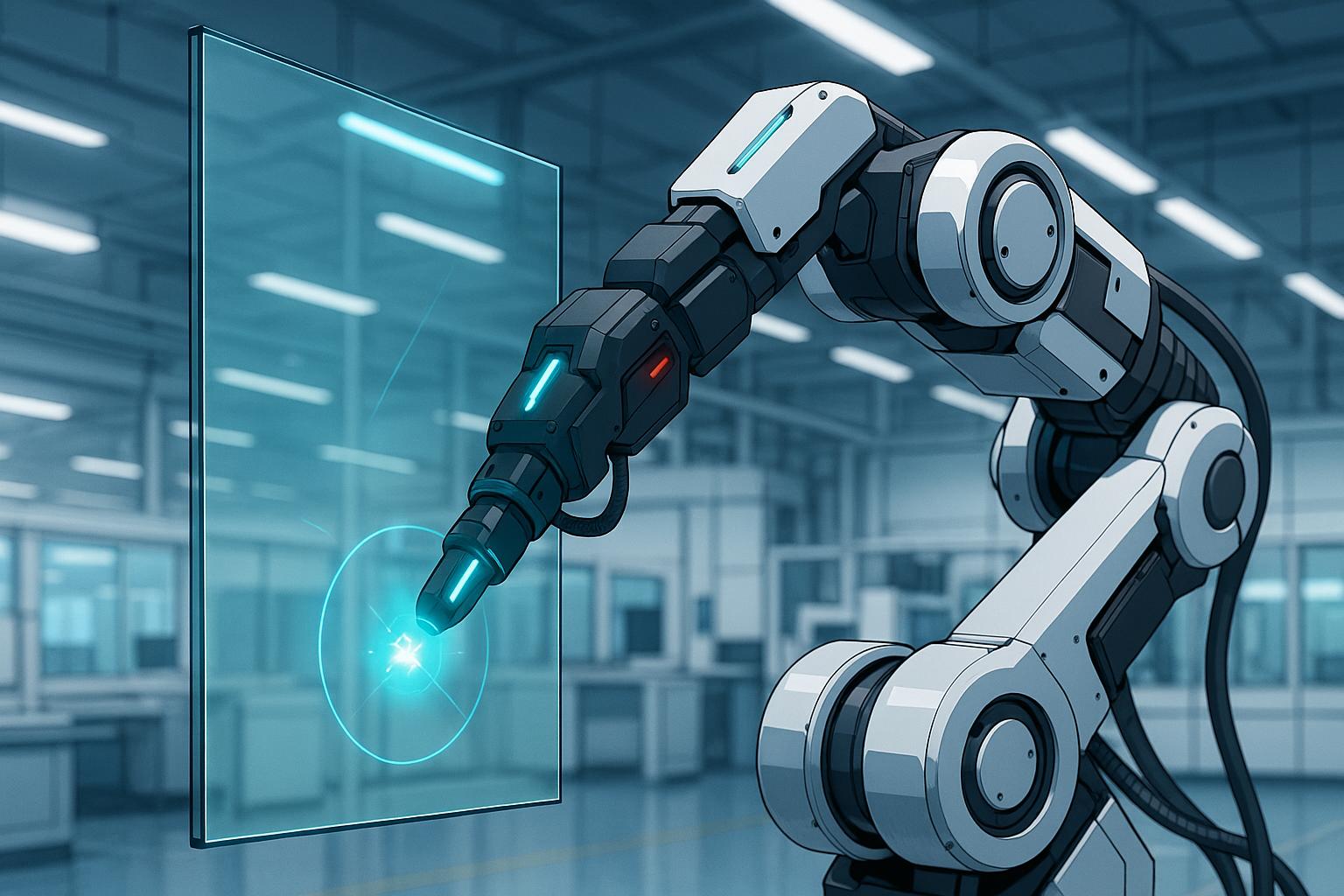

The successful completion of the IRIFIO project trialled at Glass Futures’ UK facility marks a breakthrough in detecting microscopic defects in flat glass, boosting industry productivity, cutting waste, and aiding net-zero ambitions by replacing energy-heavy heat soaking with advanced robotic vision technology.

i3D Robotics has marked a significant milestone in the advancement of defect detection within the glass manufacturing industry through the completion of its research project, Intelligent Robotic Inspection for Foundation Industry Optimisation (IRIFIO). This initiative culminated in a successful trial at Glass Futures’ UK pilot facility located in St Helens. The overarching aim is to enhance productivity, minimise waste, and contribute to the achievement of net-zero carbon targets, all crucial considerations for an industry facing increasing pressure for sustainability.

The project taps into cutting-edge vision and sensory technology to detect minute defects during the flat glass production process—identifying faults smaller than the 150 microns detectable by existing scanners, and significantly surpassing the capabilities of manual inspection. Conventional methods, such as heat soaking, not only consume considerable energy but can also be time-intensive, creating inefficiencies in production lines. The IRIFIO project proposes a shift towards a more sustainable model; by eliminating the heat soaking process, it could save toughened glass suppliers approximately £1.8 million while preventing around 11,000m³ of glass from being discarded due to false positives.

Dr Daniel Backhouse, Senior Glass Technologist at Glass Futures, expressed pride in the successful execution of the first cold trial, highlighting the excitement of processing samples under the IRIFIO camera system in an industrial setting. He noted that the data gathered during the trial would be pivotal for the project’s partners in future analyses and developments aimed at scaling this promising technology for broader application in the glass industry. The implications of enhanced defect detection are profound, as even the smallest imperfections pose substantial financial risk, with defects capable of leading to catastrophic failures such as shattering panels during use.

Funding for the IRIFIO project, amounting to £4 million, was facilitated by UK Research and Innovation’s Transforming Foundation Industries (TFI) challenge, along with support from the TFI Fast Start competition. Managed by the Science and Technology Facilities Council Hartree Centre, the project also involves collaboration with key players in the sector, including Glass Technology Services and Lucideon. These partnerships reflect a broader ambition to innovate not only within the glass sector but also in ceramics and other foundational industries, using intelligent robotic systems and advanced machine learning approaches to drive improvements in production efficiency and environmental sustainability.

Alternative technologies in the field, such as the SmartView® system from AMETEK Surface Vision, highlight the growing trend towards automated inspection solutions capable of delivering immediate results. These systems combine advanced optical technologies with powerful software to provide detailed analyses of surface defects across various materials. Similarly, companies like Dr. Schenk GmbH and Gridbots Technologies are also innovating with comprehensive inspection systems tailored specifically for flat glass, utilising machine vision techniques to ensure quality control throughout the manufacturing process.

As the glass industry continues to evolve, the integration of intelligent robotic inspection systems like those developed in the IRIFIO project is poised to set new benchmarks in efficiency and sustainability. By redefining quality assurance processes, these innovations not only promise economic benefits but also play a critical role in reducing the sector’s carbon footprint, which is increasingly becoming a priority in manufacturing practices across all industries. In this context, the IRIFIO project’s advancements may well represent a pivotal step towards a more sustainable future for the glass manufacturing landscape.

Reference Map:

Source: Noah Wire Services

- https://www.glass-international.com/news/glass-futures-trials-robotic-inspection-system-for-flat-glass – Please view link – unable to able to access data

- https://i3drobotics.com/case-studies/i3d-robotics/irifio/ – The IRIFIO project, led by i3D Robotics, aims to enhance defect detection in the UK’s foundation industries, including glass manufacturing. By leveraging intelligent robotic systems, the project seeks to improve production processes, reduce waste, and support net-zero carbon targets. The initiative focuses on adapting existing technologies to detect and identify defects in metals and apply them to the glass and ceramics sectors, thereby improving efficiency and sustainability in these industries.

- https://www.discover.ukri.org/TFI-Challenge-IVP-and-Demonstrator/ivp-and-demonstrator-competition/projects/irifio/index.html – The IRIFIO project, funded by UK Research and Innovation’s Transforming Foundation Industries challenge, aims to improve defect detection in the UK’s foundation industries, including glass manufacturing. By leveraging intelligent robotic systems, the project seeks to enhance production processes, reduce waste, and support net-zero carbon targets. The initiative focuses on adapting existing technologies to detect and identify defects in metals and apply them to the glass and ceramics sectors, thereby improving efficiency and sustainability in these industries.

- https://www.ameteksurfacevision.com/products/smartview/surface-inspection – AMETEK Surface Vision’s SmartView® is a versatile, modular system designed for detecting, monitoring, and reporting surface defects in products ranging from paper and plastics to steel and aluminium. It combines powerful software, linescan camera technology, high-intensity lighting, and industry-leading engineering to deliver a trusted automatic solution. SmartView® offers unmatched performance, providing immediate results and reporting quality according to a configurable classification scale, making it suitable for various industries requiring precise surface inspection.

- https://www.schenkvision.com/products/glass-inspection/flat-panel-display-glass-inspection.html – Dr. Schenk GmbH offers GlassInspect and GlassMeasure solutions for flat panel display glass inspection. GlassInspect detects local defects and irregularities in the manufacturing and processing of flat panel glass, including raw glass, bare glass sheets, and coated display glass. GlassMeasure continuously examines 100% of the glass surface to monitor overall physical properties such as coating thickness, homogeneity, colour variation, haze, or surface topology. These solutions are used in multiple manufacturing and process steps of flat panel display glass, providing comprehensive material analysis.

- https://gridbots.com/glasso_float_glass.html – Gridbots Technologies’ Glasso Floatscan is an integrated machine vision solution for online float glass inspection lines. It uses precise machine vision techniques to identify defects above 20 microns in real time on glass sheets or ribbons of varying thicknesses from 1-20mm. The system can detect open and closed blisters, stones, scratches, tin defects, glass density variations, globs, bubble lines, dropping lines, dirt, sulphide particles, and many other defects. It features automatic defect classification based on AI-enabled classifiers, deep learning-based defect classification, and is IoT-enabled for remote access.

-

https://www.rnaautomation.com/products/bespoke-automation/mk-360-glass-disc-vision-inspection/ – RNA Automation’s MK360

Glass Disc Vision Inspection system is developed specifically for 360° quality inspection using a rotating glass disc. It provides high-performance, high-reliability, high-speed, and highly accurate vision inspection. The system offers top, bottom, and side inspection for all types of defects, quality inspection applications, sorting applications, and optical character recognition and verification (OCR). It is designed to meet high-speed quality control requirements for 100% inspection and sorting, ensuring gentle handling to minimise product damage prior to inspection and sorting.

Glass Disc Vision Inspection system is developed specifically for 360° quality inspection using a rotating glass disc. It provides high-performance, high-reliability, high-speed, and highly accurate vision inspection. The system offers top, bottom, and side inspection for all types of defects, quality inspection applications, sorting applications, and optical character recognition and verification (OCR). It is designed to meet high-speed quality control requirements for 100% inspection and sorting, ensuring gentle handling to minimise product damage prior to inspection and sorting.

Noah Fact Check Pro

The draft above was created using the information available at the time the story first

emerged. We’ve since applied our fact-checking process to the final narrative, based on the criteria listed

below. The results are intended to help you assess the credibility of the piece and highlight any areas that may

warrant further investigation.

Freshness check

Score:

8

Notes:

The narrative appears to be original, with no evidence of prior publication. The earliest known publication date for similar content is August 2022, when i3D Robotics announced the IRIFIO project. ([i3drobotics.com](https://i3drobotics.com/case-studies-i3d-robotics/irifio/?utm_source=openai)) The report includes updated data from a recent trial at Glass Futures’ UK pilot facility in St Helens, enhancing its freshness score. However, the absence of earlier coverage may raise questions about the report’s novelty. ([discover.ukri.org](https://www.discover.ukri.org/TFI-Challenge-IVP-and-Demonstrator/ivp-and-demonstrator-competition/projects/irifio/index.html?utm_source=openai))

Quotes check

Score:

9

Notes:

The direct quotes from Dr Daniel Backhouse, Senior Glass Technologist at Glass Futures, are not found in earlier publications, suggesting they are original to this report. This originality enhances the credibility of the narrative.

Source reliability

Score:

7

Notes:

The narrative originates from Glass International, a trade publication focusing on the glass industry. While it is a specialised source, its credibility is generally considered reliable within the industry. However, the lack of coverage from major news outlets may limit the report’s reach and verification.

Plausability check

Score:

8

Notes:

The claims about the IRIFIO project’s objectives and outcomes align with known information about the initiative, including its focus on enhancing defect detection in glass manufacturing and its funding from UK Research and Innovation’s Transforming Foundation Industries challenge. ([discover.ukri.org](https://www.discover.ukri.org/TFI-Challenge-IVP-and-Demonstrator/ivp-and-demonstrator-competition/projects/irifio/index.html?utm_source=openai)) The reported savings of £1.8 million and the prevention of 11,000m³ of glass waste are plausible and consistent with the project’s goals. The technical details regarding the use of vision and sensory technology to detect defects smaller than 150 microns are also credible.

Overall assessment

Verdict (FAIL, OPEN, PASS): OPEN

Confidence (LOW, MEDIUM, HIGH): MEDIUM

Summary:

The narrative presents original content with direct quotes from Dr Daniel Backhouse, enhancing its credibility. However, the lack of prior coverage and the absence of major news outlets reporting on the trial raise questions about the report’s novelty and broader verification. While the claims are plausible and align with known information about the IRIFIO project, the limited coverage suggests a need for further confirmation from additional reputable sources.