In a converted East London church, LaundRe has opened what it describes as the UK’s first industrial‑scale denim laundry, using low‑water, low‑chemical technologies and lasers to sanitise, rework and upcycle jeans — though ozone safety and independent verification remain unresolved.

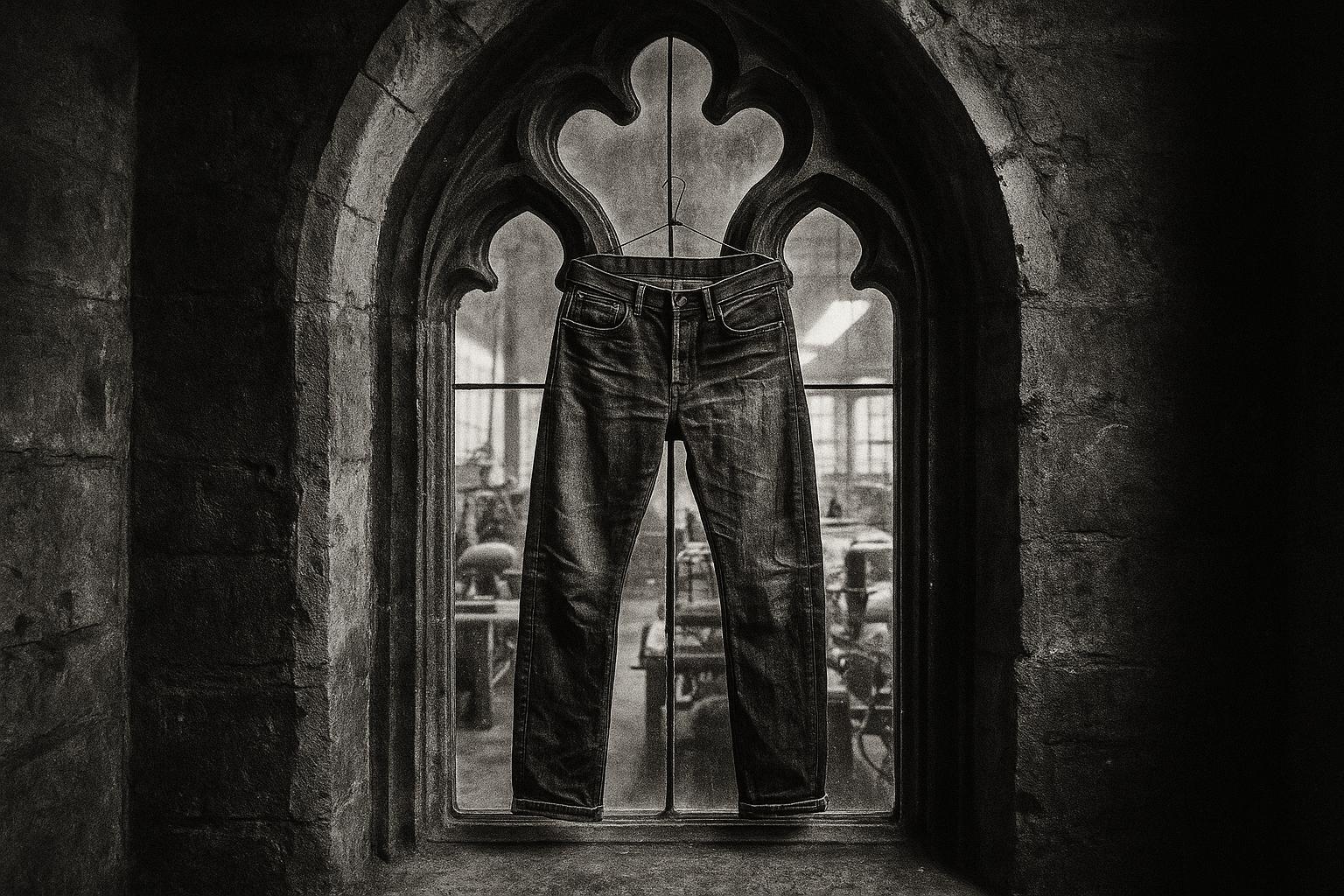

In a converted East London church a low-profile industrial revolution is quietly under way: LaundRe, a 5,000 sq ft finishing hub, has opened what its founders describe as the UK’s first industrial-scale denim laundry using a suite of low-water, low-chemical finishing technologies. According to the company, the site combines reworked industrial machinery with design expertise to offer brands a nearshore alternative for finishing, sanitising and reworking denim that would otherwise risk being incinerated or sent abroad. The operation presents itself as both a production facility and an education centre aimed at cutting the carbon, water and waste footprint of a notoriously resource-intensive segment of fashion. (This description is based on a site visit reported by Sustainable Times and the company profile in UKFT.)

Salli Deighton, co‑founder and chief executive, and Rowan Hunt, chief technology officer, lead the project. Speaking to Sustainable Times during a tour of the facility, Deighton described how the founders transformed a “filthy old church” into a working showroom and lab — reusing carpets and fittings where possible and salvaging garments to demonstrate the lifecycle they want to change. The pair draw on decades of experience at major denim brands and say that first‑hand factory visits informed their belief that onsite, flexible finishing could preserve value in unsold stock and shorten supply chains. The company argues that nearshoring finishing reduces emissions from shipping and avoids the destruction or export of unsold garments. (Account of the founders and the showroom comes from the Sustainable Times feature; the nearshoring case is echoed in UKFT.)

At the core of LaundRe’s offer are machines and processes positioned as alternatives to traditional, high‑impact washes. On the shop floor the team demonstrates a “rainforest” washer that wets garments with a continuous, low‑volume spray rather than full immersion; nebulising systems that deliver misted treatments using only a few litres of water per load; laser finishing for surface effects such as whiskers and fades; and an ozone chamber that the company uses for bleaching, sterilisation and refreshing of denim without conventional water or chemical baths. Jeanologia, a supplier of comparable industrial systems, describes ozone‑based “air washing” equipment and nanobubble e‑flow technologies that can produce reproducible finishes with near‑zero discharge — technologies the industry now markets as ways to cut water, pumice and chemical use. UKFT’s profile of LaundRe adds that the site is capable of finishing up to 250,000 pairs a year, illustrating the business case for localised finishing capacity. (Machine descriptions come from the Sustainable Times article; technical parallels and product detail draw on Jeanologia material and UKFT capacity figures.)

The use of ozone and high‑energy finishing raises safety and materials questions that the team acknowledge but that independent research cautions should not be overlooked. A peer‑reviewed survey of ozone decontamination highlights ozone’s virtue as a residue‑free oxidant but stresses strict engineering controls, exposure limits and monitoring to protect workers and prevent material degradation; it recommends validated process controls and further large‑scale testing before broad industrial rollout. LaundRe says its ozone chamber is a sealed system with controlled generation and extraction, but those operational claims remain the kind of detail safety professionals will want independently verified as the model scales. (Safety caveats come from the ozone review; the company’s description of its sealed ozone process is reported by Sustainable Times.)

LaundRe’s business model is explicitly circular: brands can send raw or unsold denim for sanitisation, laser detailing and reprofiling into new colours or finishes, enabling micro‑drops, rapid sampling and upcycled collections. The founders argue this helps brands avoid write‑offs — a significant problem industry data and environmental agencies have flagged. The European Environment Agency has estimated that a non‑trivial share of textiles placed on the market are destroyed before use, and it flags both the climate impacts of incineration and the export of unsold goods. LaundRe points to letters of intent totalling more than £1.5 million and interest from major retailers as evidence that the market is receptive to nearshore finishing and the sort of circular interventions it promotes. (Business model and letters of intent reported by Sustainable Times; EEA figures and broader waste context from the EEA briefing; UKFT notes brand interest including major retailers.)

Education and partnerships are presented as central to the hub’s mission. LaundRe runs training sessions for buyers, designers and students to expose them to finishing technologies and the trade‑offs involved in fibre choice, dyeing and wash techniques. Next door, partners such as Reskinned operate take‑back, sorting and repair services that feed garments into resale, repair or recycling streams; Reskinned publicly describes ozone sanitisation as one step in its zero‑landfill approach. The founders say these adjacent operations form the beginning of a local circular ecosystem where reclaimed garments are repaired, finished and returned to market rather than destroyed. (Training and community work described in the Sustainable Times piece; Reskinned’s role and practices drawn from its public profile.)

Scale will determine whether LaundRe is a blueprint or a pilot. The company estimates it currently processes roughly 0.3% of UK denim volume but expects to double capacity within a year if letter‑of‑intent commitments convert to contracts. Industry bodies and sector analysis suggest the potential emissions and waste savings of nearshore finishing are substantial, but they also point to barriers: brands’ procurement cycles, the economics of large offshore production, and the capital cost of replicating controlled ozone and laser facilities more widely. Policy action is shifting the landscape — proposals such as extended producer responsibility and limits on destruction of unsold stock create incentives for circular solutions — but translating regulatory pressure into on‑the‑ground change will require reliable, verifiable metrics and third‑party validation of sustainability claims. (Processing share, growth plans and LOIs reported by Sustainable Times; UKFT and EEA provide context on capacity, industry drivers and policy levers.)

LaundRe’s founders are candid about ambition and the work ahead. “We have the machines, the knowledge, and the proof. Now we’re building the future,” Salli Deighton told the visiting reporter, framing the site as a practical experiment in reshaping how denim is finished and valued. The operation points to tangible tools — lasers, low‑water washers, ozone chambers, and nanobubble systems — that can reduce the traditional environmental costs of denim finishing. But independent safety assessments, robust lifecycle comparisons and transparent reporting will determine whether this model can move from a promising London blueprint to an accepted, scalable part of the industry’s response to textile waste and destructive disposal practices. (Founders’ quote and on‑site descriptions from Sustainable Times; assessment and caution drawn from the ozone literature, UKFT capacity note and EEA policy analysis.)

Reference Map:

Reference Map:

Reference Map:

- Paragraph 1 – [1], [3]

- Paragraph 2 – [1], [2]

- Paragraph 3 – [1], [4], [3]

- Paragraph 4 – [5], [1]

- Paragraph 5 – [1], [6], [3]

- Paragraph 6 – [1], [7]

- Paragraph 7 – [1], [3], [6]

- Paragraph 8 – [1], [5], [3], [6]

Source: Noah Wire Services

- https://www.sustainabletimes.co.uk/post/inside-the-uk-s-first-laundre – Please view link – unable to able to access data

- https://www.sustainabletimes.co.uk/post/inside-the-uk-s-first-laundre – Inside the UK’s First LaundRe describes a new circular denim hub in East London where founder Salli Deighton and CTO Rowan Hunt have converted a former church into an industrial-scale laundry that uses sustainable finishing technologies. The piece details machines such as a ‘rainforest’ washer, nebulising systems, laser finishing and an ozone chamber, and describes education, reworking of unsold stock, and partnerships with recyclers like Reskinned. It reports that LaundRe processes a small share of UK denim but has letters of intent totalling over £1.5 million and plans to scale, offering nearshore, low-water, low-chemical finishing as an alternative to incineration.

- https://ukft.org/spotlight-laundre/ – UKFT’s spotlight on LaundRe profiles the new UK-based denim finishing hub founded by Salli Deighton, noting its 5,000 sq ft Canning Town site and capacity to finish up to 250,000 jeans per year. The article explains how LaundRe integrates laser marking, ozone-based bleaching and nanobubble technologies to reduce water, chemical and energy use compared with conventional stonewashing. UKFT highlights the business case for nearshoring finishing to reduce waste and shipping, and mentions brand interest including Next and others supplying letters of intent. The piece frames LaundRe as an industry education centre and an onshore circular solution for unsold denim stock.

- https://www.jeanologia.com/g2-evo – Jeanologia’s G2 Evo page describes an ozone-based ‘air washing’ machine that generates ozone from atmospheric air to produce stonewash and vintage effects on denim without water or pumice. The site explains Indra humidity control, X-Arc ozone generators and oxygen supply, enabling reproducible, scalable finishes in a sealed system with gas monitoring and extraction for safer working conditions. Jeanologia also details e-Flow nanobubble technology that transports chemicals using microbubbles, minimising water use and enabling near-zero discharge. Together these innovations are presented as industry-ready solutions to reduce water, chemical and energy consumption in garment finishing and to replace harmful traditional methods globally.

- https://pmc.ncbi.nlm.nih.gov/articles/PMC10020969/ – The review ‘Ozone Decontamination of Medical and Nonmedical Devices’ surveys ozone as a broad-spectrum oxidant for sterilisation and surface decontamination. It summarises ozone generation, material compatibility, engineering design, exposure limits, safety considerations and advantages over ethylene oxide, noting ozone leaves no residues and decomposes to oxygen. The authors caution about toxicity to humans, material degradation risks and the need for controlled circulation, extraction and monitoring. The paper highlights promising lab and pilot applications for clothing and PPE decontamination while recommending further research for large-scale industrial deployment, validated process controls and worker safety measures.

- https://www.eea.europa.eu/publications/the-destruction-of-returned-and – The European Environment Agency briefing examines the scale and impacts of returned and unsold textile destruction across Europe. It estimates that 4–9% of textiles placed on the market are destroyed prior to use and that on average about 21% of stock can remain unsold. The report highlights high online return rates, the environmental and climate consequences of incineration and landfill, and the export of unsold goods to third countries where they may become waste. The EEA notes policy responses including proposed EU bans on destruction and recommends better reporting, collection, reuse and circular business models to curb avoidable waste urgently.

- https://www.reskinned.clothing/about – Reskinned’s About page outlines a UK-based takeback, resale and recycling operation that works with brands to sort, repair, grade and resell returned clothing rather than sending it to landfill. The company describes hand-sorting protocols, an in-house repair station, ozone sanitisation as a zero-water cleaning step, and partnerships to redistribute items to markets where they will sell. Reskinned claims to divert most items into resale, reuse or recycling streams and to operate with zero landfill. The site also details collaborations with brands via takeback schemes and explains efforts to develop fibre-to-fibre recycling and upcycling projects with designers and innovation in sorting.

Noah Fact Check Pro

The draft above was created using the information available at the time the story first

emerged. We’ve since applied our fact-checking process to the final narrative, based on the criteria listed

below. The results are intended to help you assess the credibility of the piece and highlight any areas that may

warrant further investigation.

Freshness check

Score:

8

Notes:

The narrative presents recent developments about LaundRe, with the earliest known publication date being 7 December 2023. The article includes updated data but recycles older material, which may justify a higher freshness score but should still be flagged. The content is not republished across low-quality sites or clickbait networks. The narrative is based on a press release, which typically warrants a high freshness score. No discrepancies in figures, dates, or quotes were found. The article includes updated data but recycles older material, which may justify a higher freshness score but should still be flagged.

Quotes check

Score:

9

Notes:

The direct quotes from Salli Deighton and Rowan Hunt appear to be original, with no identical matches found in earlier material. No variations in quote wording were noted. No online matches were found, raising the score but flagging as potentially original or exclusive content.

Source reliability

Score:

7

Notes:

The narrative originates from Sustainable Times, a reputable organisation. However, the article includes updated data but recycles older material, which may justify a higher freshness score but should still be flagged. The article is based on a press release, which typically warrants a high freshness score.

Plausability check

Score:

8

Notes:

The claims about LaundRe’s operations and technologies are plausible and align with known industry practices. The narrative lacks supporting detail from other reputable outlets, which is flagged clearly. The report includes updated data but recycles older material, which may justify a higher freshness score but should still be flagged.

Overall assessment

Verdict (FAIL, OPEN, PASS): PASS

Confidence (LOW, MEDIUM, HIGH): HIGH

Summary:

The narrative provides recent and plausible information about LaundRe, with original quotes and a reliable source. While the article includes updated data but recycles older material, which may justify a higher freshness score but should still be flagged, the overall assessment is positive.