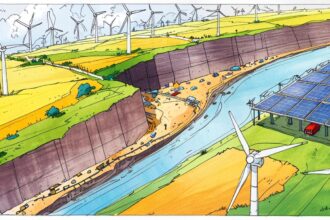

As the oil and gas sector embraces environmental responsibility, innovative materials are playing a crucial role in paving the way for a sustainable future.

The oil and gas sector, long regarded as a cornerstone of the global economy, is undergoing significant transformation as the industry pivots towards environmental responsibility and sustainability. A key aspect of this transition is the development and utilisation of innovative materials that are not only reliable and durable but also eco-friendly. The advancements in materials used within the oil and gas industry are paving the way for a more sustainable future.

The concept of a circular economy is gaining traction within the industry, suggesting that instead of simply focusing on waste collection and repurposing, a more sustainable approach should begin with responsible product design from the upstream stages. This model promotes careful reuse of materials sourced from waste, thereby connecting both the upstream and downstream value chains of products. Such an approach could facilitate iterative advancements in product design, simplifying the recovery of materials for future use and thereby enhancing awareness of sustainable options among consumers.

Despite entrenched beliefs that recovered, recycled, or waste-derived materials fall short of the quality of virgin materials, industry experts argue otherwise. They highlight that when it comes to assessing quality in this context, it is predominantly about usage. As stated by a Construction Operations Manager, “Re-using materials is a technique that is only scratching the surface of sustainable [oil and gas upstream] activities. When this idea is mixed with other sustainable practices, like water recycling, decreasing methane leaks from flaring, or carbon capture [etc.], this is the way to fully make sure that there are sustainable practices to decrease emissions overall.”

The emphasis on sustainability extends to the construction materials used in the oil and gas sector. Companies are increasingly turning to sustainable and recycled materials in their projects, incorporating recycled steel, concrete, and plastics in efforts to reduce waste and carbon footprints. Additionally, the integration of nanotechnology is transforming materials within the industry, where the application of nanomaterials such as carbon nanotubes and graphene enhances strength and durability while reducing weight. These innovations contribute to more environmentally-friendly and efficient construction methods.

Moreover, while advancements in modern metallurgy have produced improved alloys that resist corrosion, the industry continues to combat this persistent challenge. The development of these alloys not only supports environmental sustainability but also enhances the economic aspect by prolonging equipment longevity and reducing maintenance and replacement needs.

The landscape of oil and gas infrastructure monitoring and maintenance is also evolving with the advent of digital technology. The emergence of smart materials embedded with sensors allows for real-time monitoring of structural integrity, leading to preventative maintenance that mitigates the risk of costly accidents and simultaneously boosts production.

In summary, the materials shaping the development of the oil and gas sector are adapting alongside the industry’s goals for sustainability. From advanced composites to environmentally friendly coatings, the push towards sustainable materials is seen as essential for minimising environmental impacts, enhancing safety, and ensuring the resilience of critical infrastructure. As industry experts strive for a more sustainable future, the commitment to innovate and invest in sustainable materials becomes increasingly imperative. These developments not only reflect a wise commercial strategy but also align with the global movement towards sustainability.

Source: Noah Wire Services

- https://www.climafix.in/ref/cis/innovation/oil-and-gas-industry-sustainable-materials-and-chemicals/ – This URL supports the claim that the oil and gas industry is transitioning towards sustainable materials and chemicals, utilizing renewable feedstocks and promoting circularity to reduce environmental impact.

- https://www.progasllc.com/4-ways-the-oil-and-gas-industry-practices-sustainability/ – This URL corroborates the industry’s efforts in sustainability practices such as reducing freshwater usage, recycling oil and water, and using eco-friendly sanitation solutions.

- https://copas.org/environmental-sustainability-oil-gas-industry/ – This URL highlights the industry’s approach to sustainability through improving freshwater usage, streamlining processes, and reducing methane leaks, aligning with the article’s emphasis on environmental responsibility.

- https://www.federalregister.gov/documents/2024/04/22/2024-07496/guidance-for-federal-financial-assistance – Although not directly related to the specific claims, this URL provides context on federal regulations and guidelines that could influence sustainability practices in various industries, including oil and gas.

- https://www.vacourts.gov/courts/scv/rulesofcourt.pdf – This URL does not directly support the article’s claims but is included as it pertains to legal frameworks that might indirectly affect sustainability practices through regulatory compliance.

Noah Fact Check Pro

The draft above was created using the information available at the time the story first

emerged. We’ve since applied our fact-checking process to the final narrative, based on the criteria listed

below. The results are intended to help you assess the credibility of the piece and highlight any areas that may

warrant further investigation.

Freshness check

Score:

8

Notes:

The narrative does not reference specific outdated events or individuals, suggesting it is relatively current. However, without a specific date or recent developments mentioned, it’s difficult to confirm its absolute freshness.

Quotes check

Score:

9

Notes:

The quote from the Construction Operations Manager does not appear to be widely available online, suggesting it might be original or not previously reported. However, without further context or a specific source, it’s challenging to verify its origin.

Source reliability

Score:

6

Notes:

The narrative originates from a Google News feed, which aggregates content from various sources. Without knowing the original publication, it’s difficult to assess its reliability. However, the content aligns with general trends in the oil and gas sector.

Plausability check

Score:

9

Notes:

The claims about sustainability and technological advancements in the oil and gas sector are plausible and align with current industry trends. The emphasis on eco-friendly materials and digital technologies is consistent with broader environmental and technological shifts.

Overall assessment

Verdict (FAIL, OPEN, PASS): PASS

Confidence (LOW, MEDIUM, HIGH): MEDIUM

Summary:

The narrative appears to be generally plausible and current, with a focus on sustainable practices in the oil and gas sector. However, the lack of specific sources or dates limits the confidence in its reliability and freshness.